Digital Engineering

Digital transformation is changing the manufacturing sector to smart and data driven. It is about 4.0 technology for machines and plants, which, besides being virtual, become intelligent and take us straight into the fourth industrial revolution. Discover the benefits of virtual and augmented reality for industry: become a protagonist with Applied Industrial Innovation.

Digital Engineering: Industry 4.0 and user digital experience

Digital transition and technological transformation in Industry 4.0

The manufacturing industry is increasingly connected with data science and the development of virtual environments: it is in the midst of a digital transformation.

From machine design to machine upgrades, nothing is the same as before.

Through digital engineering technologies it is possible to “escape” the physical environment and take advantage of all the benefits of virtual commissioning and industrial metaverse.

We at Applied Industrial Innovation are also here for this: to offer your company everything it takes to be the protagonist of this revolution.

Virtual commissioning e Digital Twin per la prototipazione e collaudo di impianti industriali

The manufacturing sector has always been more receptive to technological innovations. Today, it is the forerunner of industrial digitisation through the implementation of intelligent connected machines integrated with the automation of the production and distribution chain: artificial intelligence opens the door to the fourth industrial revolution.

Enter this new era with Applied Industrial Innovation! We can accompany you in supply chain management by digitising the process of machine design, development and production. A radical change that has a significant impact on the prototyping and realisation of the final system.

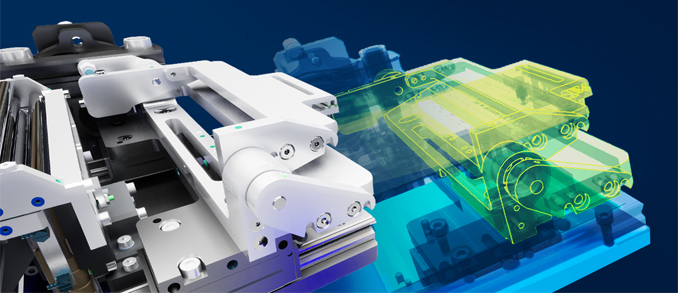

Following the creation of a digital twin (virtual model of an object), virtual commissioning of the plant prototype takes place.

This allows to test and validate the PLC, the real brains of the machinery, even before the physical apparatus of the plant is built: lower product testing and maintenance costs and reduced machine commissioning times.

We have the skills to realise an entire plant with virtual commissioning, a technological process whereby a virtual model of the machine is linked to the real electronic part in order to easily develop state-of-the-art software.

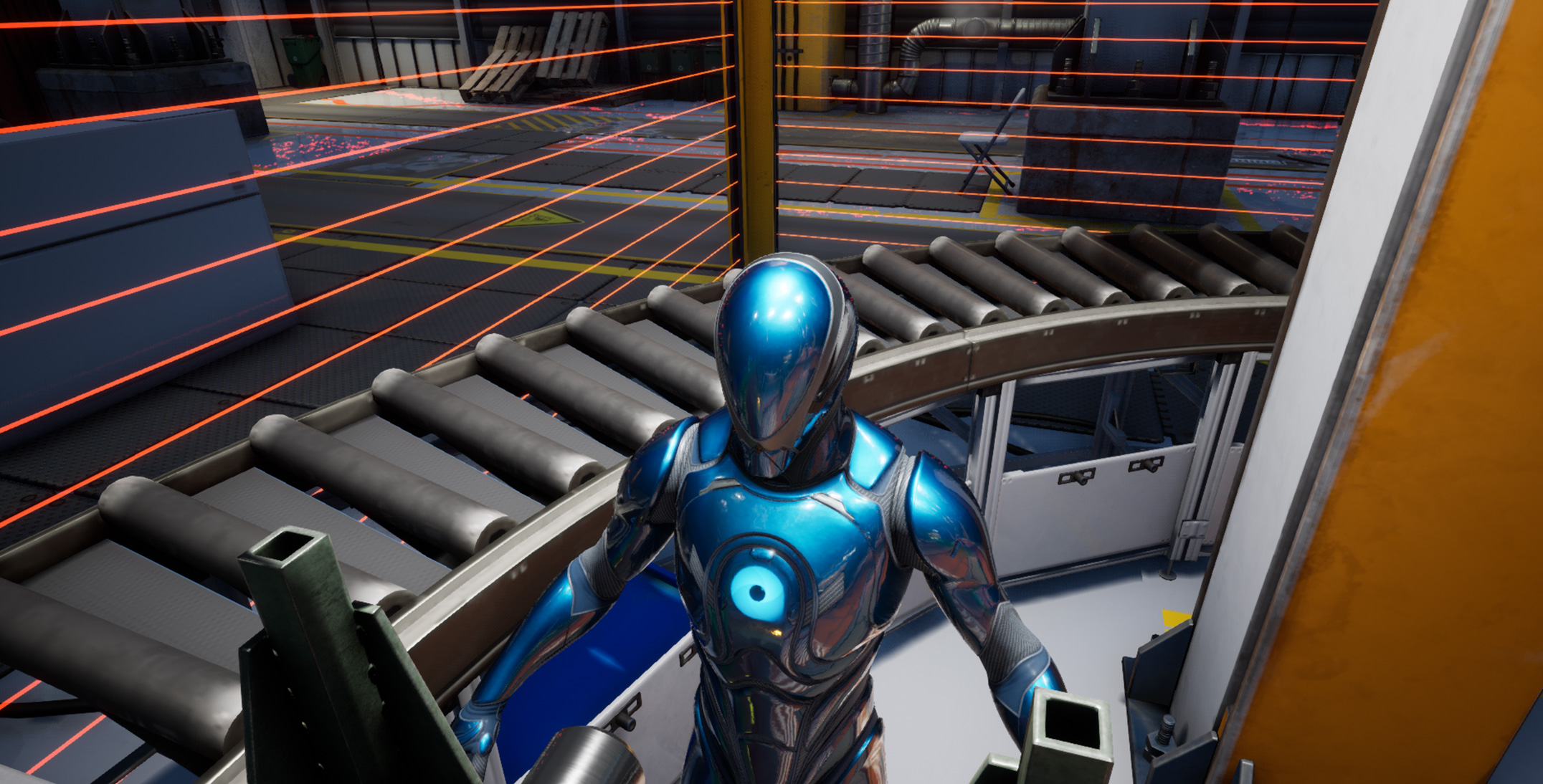

And that's not all. Through Plant Simulation, it will be possible to model production and logistics projects, going so far as to create an entire virtual factory in order to evaluate not only its production flow, but also its ergonomics and safety for the machine operator. These are the benefits of virtual and augmented reality for industry.

The Applied Competence Center, specialized in industrial simulation, offers support and consulting services to companies for simulation projects involving machine modules, plants, the creation of digital twins, and their integration with physical models. We manage and develop simulation projects using platforms such as Machineering, FlexSim, SIEMENS, and UNREAL.

InnovationStories

Discover all storiesApplied Industrial Innovation's digital engineering and prototyping services for industrial plants

Our services

Discover all servicesAI & Data driven services

Choose Applied Industrial Innovation for consulting in Industrial IOT and the application of artificial intelligence models for industry. Enter the world of connected machines.

Read moreQuality & Process Validation

Applied assists and supports companies in the pharmaceutical, medical, cosmetic and food sectors by providing advice and support in the creation of qualification and validation documents, as well as useful tools for verifying, maintaining and archiving the information that is produced during the design and testing of automation systems.

Read moreInformation Security

Applied supports companies in the manufacturing sector through specialized consulting services in the field of Information and Cyber Security, with a particular focus on compliance with the ISO/IEC 27001:2022 standard and the NIS2 Directive. The offering includes Gap Assessment, Auditing, and operational support throughout the regulatory and certification compliance process, with the aim of ensuring information protection, compliance with requirements, and constant updating through targeted training.

Read more