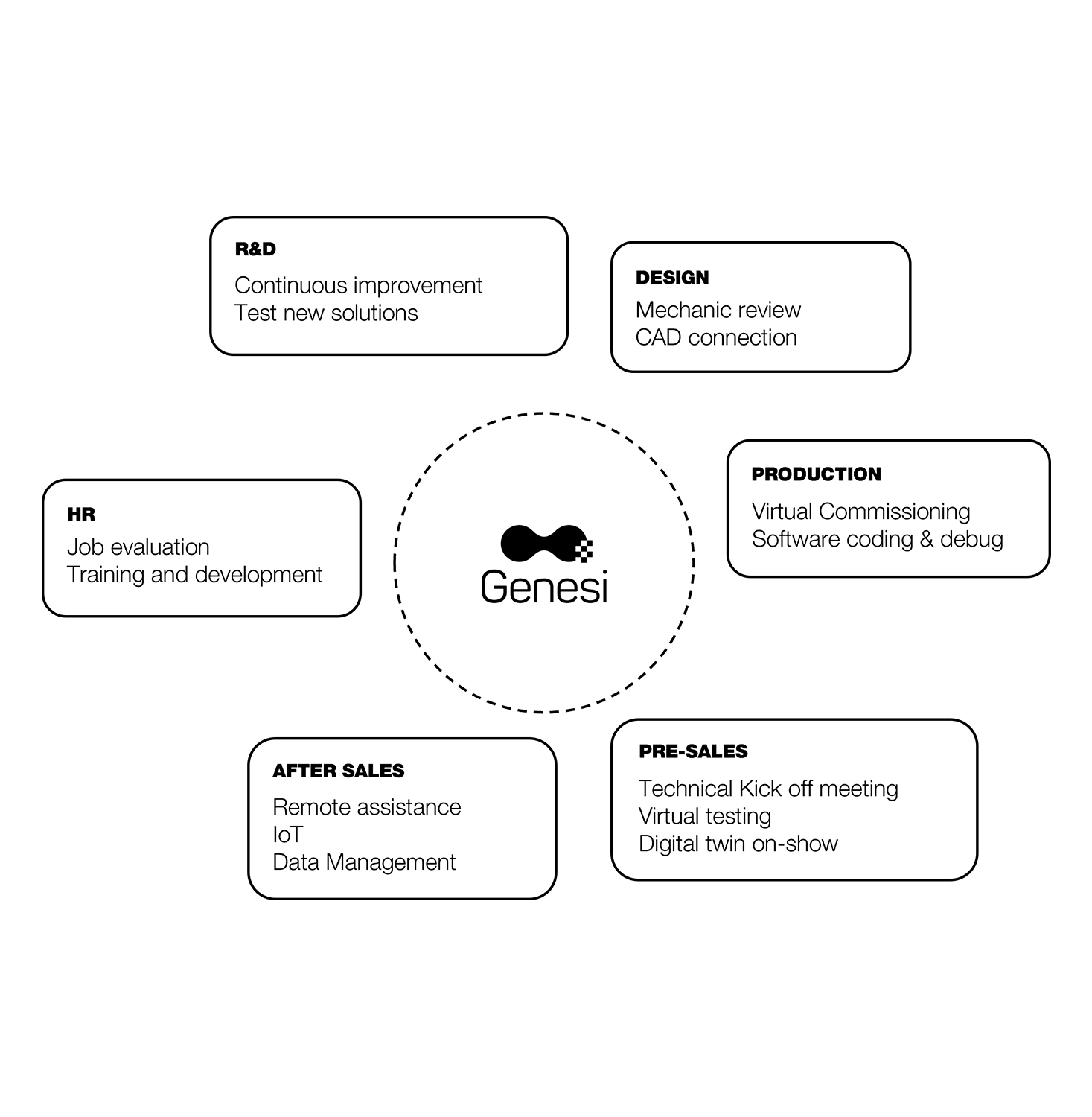

Genesi, industrial simulation and digital twin

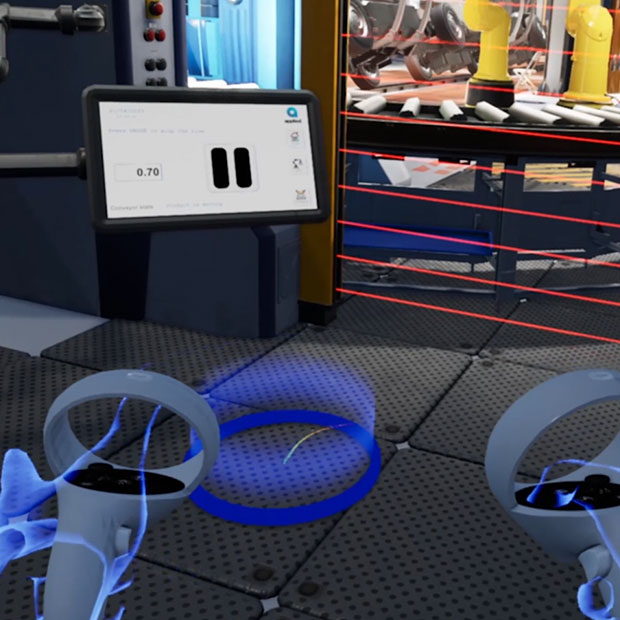

Genesi is an advanced platform for the creation and management of industrial Digital Twins. Designed to support engineers, system integrators, and operators, it enables the full virtualization of machines and systems.

Learn more about GenesiImprove design processes with industrial digital twins

Genesi receives real-time data from PLCs, sensors, and HMIs via IoT connections. This data is synchronized with an interactive 3D digital model that faithfully replicates the behavior of the machine.

Optimizes the product life-cycle.

Genesi enhances design, training, and monitoring, increasing efficiency and safety in production processes.

The ultimate solution for R&D, production and sales.

Commissioning & PLC debugging software.

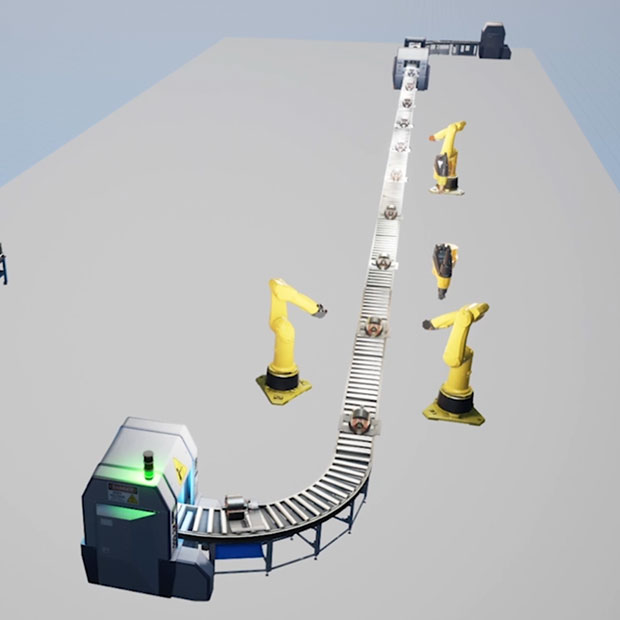

Simulation of machine modules, whole machines or entire production lines - Process simulation

Connection and integration with IoT and AI systems.

Reproduction and visualization of data collected on the actual machine to enable software optimization evaluations and tests.

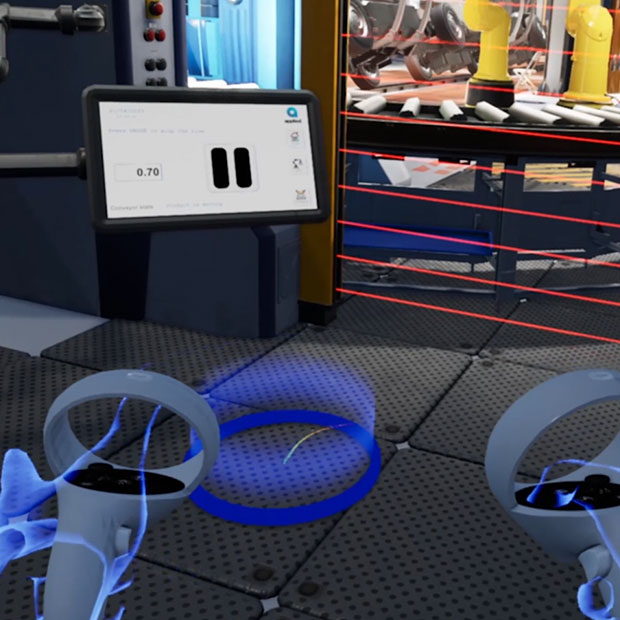

Training on machine HMIs or entire systems.

Training on virtual machines connected to real PLCs and HMIs that enable realistic reproduction of the behavior of the entire system.

Innovation for sales & after sales areas.

Presentation of machines or entire production lines with interactive and immersive experiences.

The ultimate solution for R&D, production and sales.

Commissioning & PLC debugging software.

Simulation of machine modules, whole machines or entire production lines - Process simulation

Connection and integration with IoT and AI systems.

Reproduction and visualization of data collected on the actual machine to enable software optimization evaluations and tests.

Training on machine HMIs or entire systems.

Training on virtual machines connected to real PLCs and HMIs that enable realistic reproduction of the behavior of the entire system.

Innovation for sales & after sales areas.

Presentation of machines or entire production lines with interactive and immersive experiences.

Achieve more with Genesi and Applied's competence center.

Data collection and optimization using AI.

Data collection from the physical model and optimization and testing on virtual model also by integrating AI functions.

Materials and fluids simulation.

Analysis of material behavior based on physical properties and wear.

Ergonomics testing.

Testing and ergonomic evaluation of machines and entire industrial systems.

Industrial simulation competence center

Applied's competence center specializing in industrial simulation offers support and advice to companies for different simulation projects, including machine modules, systems, digital twin creation and their connection with the physical model.